Imagine this: your product is top-notch and its demand is rising.

But then — delays, stockouts, missed deliveries. The customer experience falters, and suddenly, your reputation is impacted. What went wrong?

Most often, the answer lies in the distribution.

In today’s hyper-connected world, the moment between a sale and a delivery is more critical than ever. Customers expect speed. Businesses expect visibility.

And you? You need control.

That’s why distribution management is more than just moving goods — it’s about orchestrating people, processes, partners, and platforms to ensure the right product reaches the right place, at the right time, every time.

What Exactly Is Distribution Management?

Think of distribution management as the bridge that connects your finished product to the customer.

It encompasses every activity related to moving goods from the manufacturer or producer to the final point of sale. That includes inventory control, warehousing, packaging, order processing, logistics coordination, and managing third-party partners like wholesalers or retailers.

A well-implemented distribution management system ensures that the right product reaches the right place at the right time—without inflating costs or compromising customer satisfaction.

While distribution management focuses on the flow of goods from the manufacturer to the end customer, it’s closely intertwined with logistics.

But how exactly do these two functions differ, and why is it important to understand the distinction? Let’s break it down.

Distribution vs. Logistics: What’s the Difference?

While often used interchangeably, distribution and logistics aren’t quite the same.

Logistics refers to the intricate planning and coordination of moving goods, including transport, storage, fleet routing, customs, and tracking. It’s the backbone of your supply chain.

Distribution management, on the other hand, is more customer-centric. It focuses on fulfilling orders through various channels and ensuring the products reach their intended destination in optimal condition.

You can think of logistics as the engine, and distribution as the roadmap to customer delivery.

Now that we’ve clarified the difference between logistics and distribution management, let’s dive into why mastering distribution management is essential for businesses aiming to stay competitive, meet customer demands, and streamline operations in an ever-evolving market.

Why Does Distribution Management Matter So Much?

At its core, distribution management is about operational excellence and customer satisfaction. If a company can’t fulfill orders accurately and on time, it risks damaging its brand, losing customers, and wasting resources.

Strong distribution management leads to:

Lower operational costs through smart inventory and warehouse planning

Reduced delivery times and improved customer service

Greater adaptability to market changes and disruptions

A more agile and responsive supply chain

In short, distribution is where strategy meets execution.

To achieve these benefits, it’s crucial to have a solid understanding of your distribution network.

Let’s explore how a well-structured network can serve as the backbone of your distribution strategy, enabling you to optimize operations and deliver value at every touchpoint

Building the Backbone: Understanding Distribution Networks

A distribution network is a system of storage facilities, transport systems, and sales intermediaries. It defines how goods flow from manufacturer to consumer, whether directly or through multiple channels.

Well-designed distribution networks:

Enable faster product movement through regional hubs

Minimize shipping and handling costs

Allow companies to scale operations smoothly

Provide better geographic reach and service coverage

And with the rise of digital tools, many modern networks now rely on real-time data, automation, and integrated platforms to make smarter, faster decisions.

However, even the most robust distribution networks can face significant challenges. Without proper management, inefficiencies and missteps can disrupt the flow of goods and hinder your operations.

Let’s take a closer look at some common pitfalls that can derail even the best-laid distribution plans.

Common Pitfalls in Distribution Network

Even the best systems aren’t shielded from challenges. Distribution management faces both predictable and unexpected disruptions.

Some common hurdles include:

Natural events: weather disruptions, pandemics, or raw material shortages

Transportation delays: due to infrastructure issues or vehicle breakdowns

Economic shifts: including currency fluctuations or sudden demand drops

Product-specific issues: like recalls, packaging errors, or storage failures

Customer-side disruptions: last-minute order changes, address corrections, or bulk returns

The key is to build a distribution system that’s resilient and flexible enough to handle these challenges.

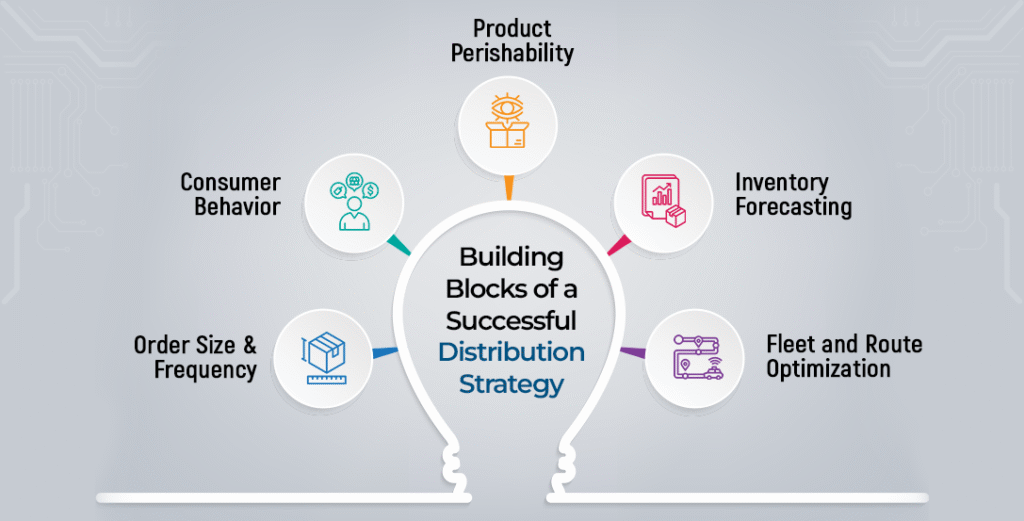

Factors That Shape a Successful Distribution Strategy

Not every product or market has the same needs. These five key variables play a major role in shaping your distribution management strategy:

Product perishability – Perishable goods require speed and often cold-chain solutions. Non-perishables can use slower, bulk-oriented methods.

Consumer behavior – Shopping patterns, seasonal spikes, and promotional campaigns influence how inventory and shipping should be managed.

Order size and frequency – High-frequency, small-order models need different workflows than bulk shipments.

Inventory forecasting – Accurately predicting demand helps prevent overstocking or understocking.

Fleet and route optimization – Ensuring every delivery vehicle is fully utilized and efficiently routed saves time and money.

Smart distribution management systems help orchestrate all these variables seamlessly.

With these key factors in mind, it’s important to recognize that distribution strategies aren’t one-size-fits-all.

The next step is understanding how different distribution categories influence these strategies and help businesses cater to diverse customer needs efficiently.

The Art of Distribution: Mass, Selective, or Exclusive?

Every business must decide how broadly to distribute its products. The three main strategies are:

1. Mass Distribution : Used when the goal is to reach the widest possible market. Think everyday essentials or fast-moving consumer goods—available everywhere, from hypermarkets to corner stores.

2. Selective Distribution : Here, products are sold through a limited but well-chosen set of intermediaries. Ideal for companies wanting some market control while still reaching a wide audience. Electronics and mid-range apparel often follow this model.

3. Exclusive Distribution : Reserved for high-end or luxury items. The brand partners with a very small number of retailers, often in specific geographies, to preserve its prestige and pricing power.

Each strategy must align with your brand positioning, customer expectations, and operational capabilities.

Once you’ve chosen a distribution strategy, the next step is deciding on the specific channels that will get your product from point A to point B.

These channels are the various pathways your product will travel through to reach your end consumer.

Understanding and selecting the right distribution channels is crucial for executing your strategy effectively and ensuring a seamless customer experience.

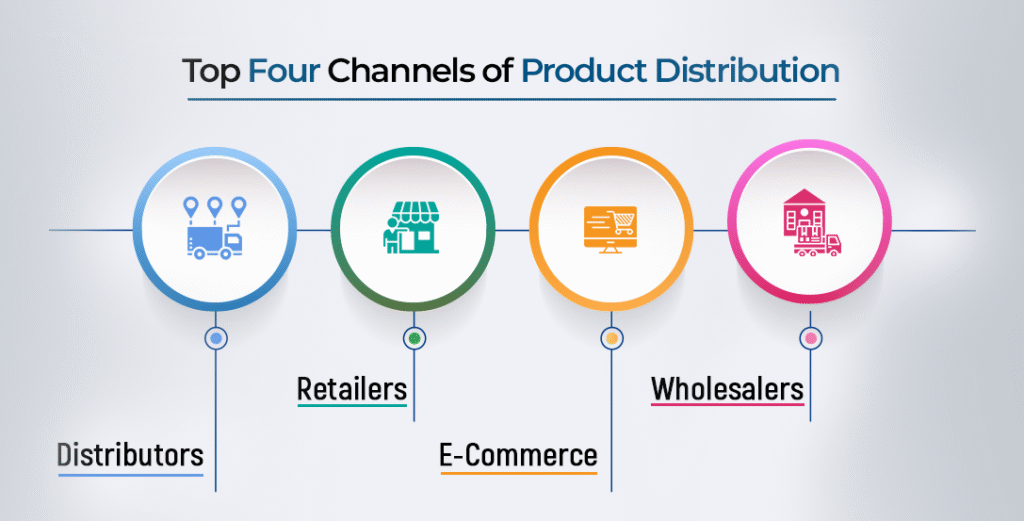

The 4 Key Channels of Distribution

No matter what you sell, you’ll likely use one or more of these four major distribution channels:

Wholesalers – Buy in bulk from manufacturers and sell to retailers. Efficient for large-scale distribution but offers less control over brand experience.

Retailers – Sell directly to consumers, either through stores or digital platforms.

Distributors – Act as intermediaries who specialize in specific industries or regions. Great for expanding reach without building your own sales team.

E-commerce – Direct-to-consumer via digital storefronts. Offers the highest margins and full control over customer experience but requires robust logistics.

A modern distribution management approach blends these channels depending on product type, customer base, and geographic priorities.

With these distribution channels in mind, the next critical step is selecting the right distribution management software (DMS).

The ideal DMS integrates seamlessly across these channels, helping you manage complexity and scale efficiently, ensuring smoother operations and better decision-making as you navigate today’s dynamic marketplace.

How to Choose the Right Distribution Management System?

A distribution management system (DMS) acts as your command center, integrating inventory, order processing, logistics, and customer data in one platform.

When evaluating a DMS, look for:

Ease of integration: Can it plug into your existing ERP, CRM, or accounting systems?

Real-time data: Visibility into stock levels, order status, and delivery timelines

Scalability: Will it support your growth across markets and product lines?

Security and compliance: Especially important for regulated industries

User experience: Intuitive dashboards and automation reduce human error and training time

The right DMS turns distribution into a competitive advantage—not a cost center.

Choosing the right Distribution Management System is crucial, but the real benefits come when the system works smoothly with your business.

That’s where EAZY DMS stands out. It helps you improve every part of your distribution network.

Optimizes Your Distribution Network with EAZY DMS

EAZY DMS acts as the brain of your distribution ecosystem—monitoring every order, stock movement, and delivery route in real time. With its powerful capabilities, it helps businesses:

Automate Order Processing: Streamline order workflows, reducing manual errors and ensuring faster order fulfillment.

Ensure Timely Stock Replenishment: Keep your inventory balanced across regions with automatic stock replenishment triggers, avoiding stockouts and overstocking.

Optimize Inventory Levels: Maintain ideal stock levels at each distribution point, reducing waste and enhancing operational efficiency.

Analyze Distributor and Retailer Performance: Get real-time insights into distributor and retailer metrics, helping you fine-tune strategies and boost performance.

Adapt to Shifting Demands: With built-in agility, respond to market fluctuations, seasonal demands, and unforeseen disruptions promptly.

Whether you’re expanding into new territories or optimizing last-mile delivery, EAZY DMS offers the transparency, control, and flexibility you need to stay ahead of the competition.

Bottom Line

Today’s market isn’t just about making great products—it’s about delivering them faster, better, and smarter. That’s where distribution management steps in.

A strong DMS allows businesses to:

Adapt swiftly to change

Scale with confidence

Deliver superior customer experiences

Maximize profitability by cutting distribution waste

So whether you’re a startup building your first channel or a large enterprise optimizing a global network, mastering distribution management could be your biggest advantage in an increasingly complex world.